Laser Metal Cutting: Precise, High-Speed, And At Low Cost

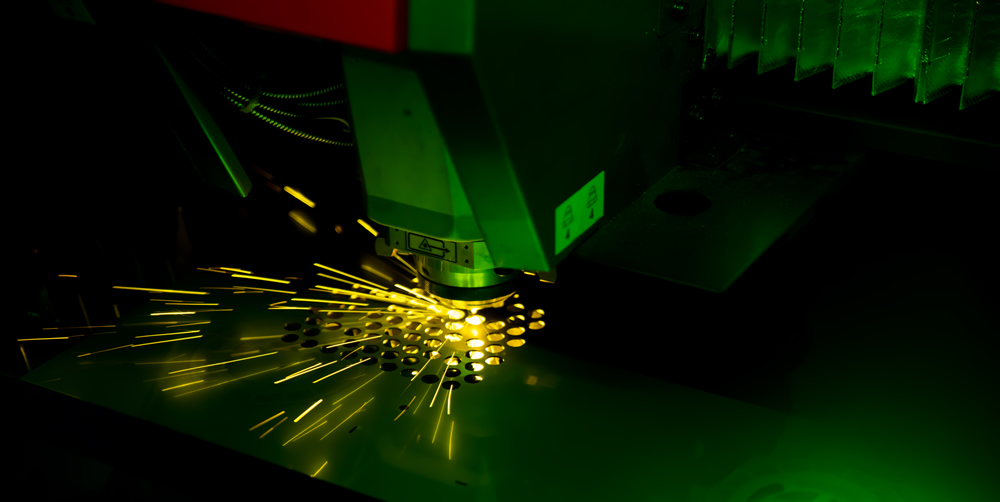

Amada Fiber Laser Machine

We pride ourselves in investing in the latest manufacturing and industrial laser cutting technology, not only to deliver consistently superior quality, but to actively support the success of our customers’ business through rapid turnaround and competitive pricing.

Our fiber laser cutting services (UK spelling: fibre) enable us to carry out fast precision laser cutting on a variety of sheet metals of different thicknesses. We can deliver this service to you either as part of our end-to-end fabrication processes or as a standalone, subcontracted offering.

Our Amada Fiber Laser incorporates a 21-tonne material tower storage system and autoloader that enables it to operate ‘lights out’ through the night, and a high-speed precision laser that cuts right first time.

This combination of huge capacity and rapid throughput enables you to get large projects delivered fast, but at lower cost – including even complex custom laser cutting jobs.

Our fiber laser cutting service: the benefits

Our Amada Fiber Laser is a commercial laser cutter that cuts at high speed through many different kinds of metals of many different thicknesses, in sheets up to 3000mm long and 1500mm wide.

It’s a winning choice for your sheet metal cutting jobs because it combines extreme precision (+/- 0.2mm) with maximum throughput and automated operation – meaning lead times are shorter, your finished components reach you quicker, and your productivity is uninterrupted.

Aside from these business benefits, our Amada Fiber Laser also beats more traditional cutting methods too, because:

- It cuts with equal precision through both mild steel and stainless steel

- It cuts both ferrous and non-ferrous metals, including aluminium, brass, copper, Zintec and other reflective materials

- It cuts at low temperature

- It cuts cleanly, using nitrogen from a dedicated generator

- It can cope with thicker metals – up to 6mm brass and copper, 14mm aluminium, 16mm stainless steel, 22mm mild steel

- It eliminates additional costs and lead time caused by corrective secondary processes like deburring, as the cleanliness and precision of the cut makes these processes unnecessary

Fiber laser cutting: productive through the night

Fiber Laser in Action

Because our metal laser cutting services feature a sheet storage tower with an autoloader system, sheets can be introduced, lasered and unloaded automatically throughout the night if necessary.

Once the tower is loaded, the correct sheet material is selected and loaded into the laser automatically. The sheet is laser cut to completion and unloaded from the laser back onto the tower. The laser is then reloaded with another sheet.

This process continues unattended – meaning you can enjoy 24/7 productivity at a price that is not increased by our own night lighting, heating and operator costs!

Going beyond the metal laser cutting process

As a full-service sheet metal fabrication business, we don’t stop with the cutting!

We can add value to your finished product in many other ways, too, at the same time and from the same location, eliminating the need for you to manage multiple suppliers and disparate workflows, and the costly delays that these can cause.

Our Amada CO2 Laser/Punch combination machine enables us to punch, dimple, countersink, louvre and tap holes, with an extensive selection of tooling to suit your every need.

And we offer a comprehensive range of other in-house services to get your sheet metal components rapidly to finished state, too, including Folding, Welding, Powder Coating and Product Assembly.

How we get your laser cut components to you

With our own low-emission, economical delivery vehicles, and our Bedford location, we’re ideally positioned to deliver your finished laser cut components to you wherever you are in the country, without costly haulage, courier or fuel charges.

But in this matter, as in all others, we are flexible – we’ll fit in with your preferences wherever we can.

If you choose to collect your components from us, we’re here six days a week to make sure it can happen.

Customer Testimonials

Just a short note to let you know that we shipped our final container on Friday of last week, thereby completing the Walmart program and all on time. As you will know, we never doubted we’d do it but we all expected setbacks and therefore an overrun at the very least. To be frank we had several setbacks, some own goals, some supply chain and one real below the belt quality issue. That said, we avoided overrun and hit the delivery date is a fantastic achievement for which we would like to extend our thanks to you and your team. I am sure we tested patience and goodwill but despite that Kempston Limited performance was outstanding in that there weren’t any disturbances to supply. An amazing job Many thanks to you all

Manufacture & fabrication of Frames, Chassis, Brackets, Front Panels, Cages, Control Units, Electronic Enclosures, Switch gear cabinets, Pedestals, Lockers, Audio Desks for the music industry, Trays, Sub-Frames, Earth Clamps & Doors as well as almost anything you can conceive in Mild Steel, Zintec, Stainless Steel & Aluminium.

We are members of: